Brand:Chuangling

Product origin:China

Delivery time:45 days

Supply capacity:Mass production

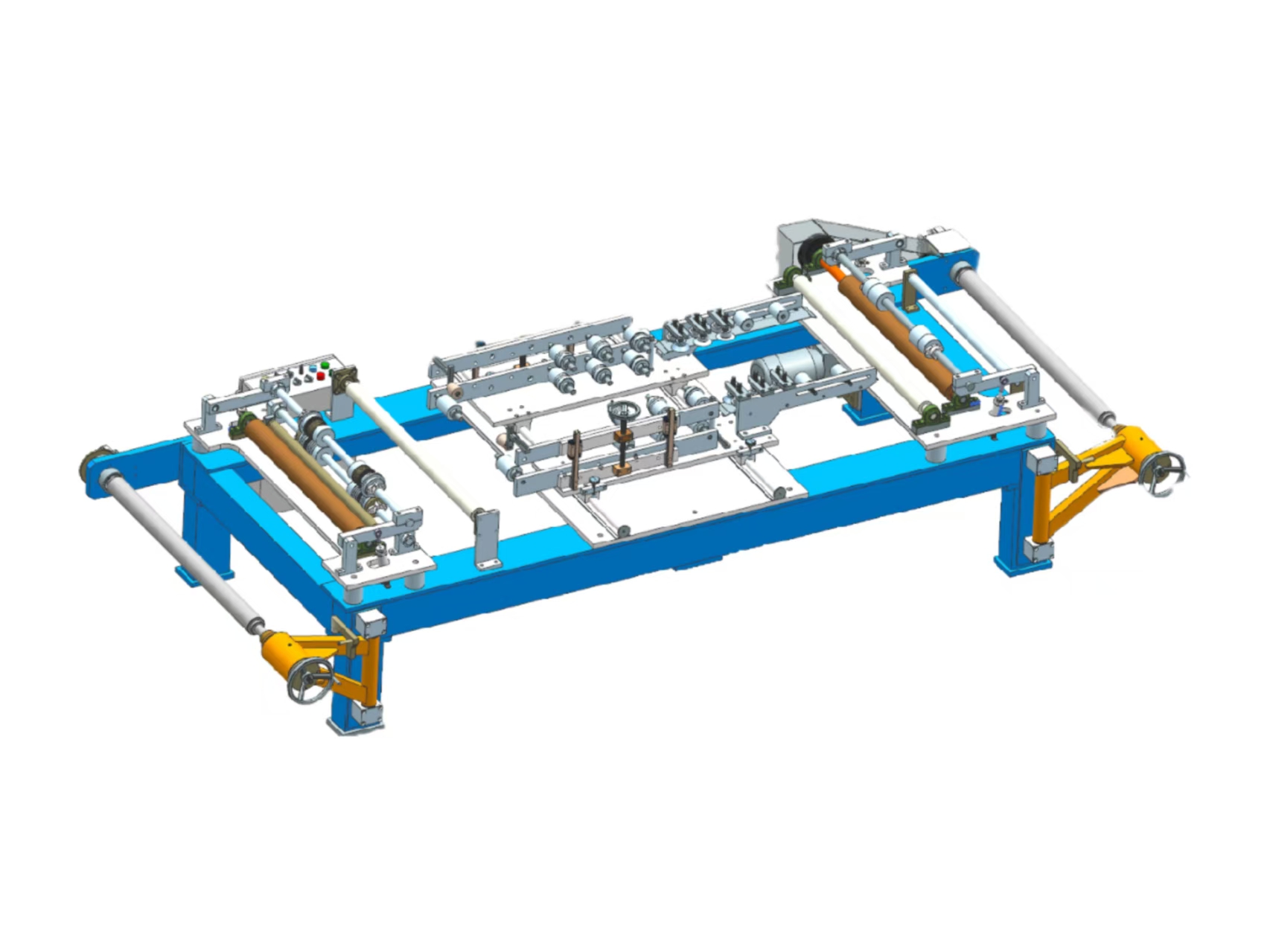

Layer Insulation Flanging Machine

Model No.: ZBJ-800

Core Positioning

Designed for precision edge-forming of interlayer insulation paper in transformer coils. Utilizes bilateral edge-shaping technology to enhance mechanical strength, winding efficiency, and material utilization. Optimized based on US-imported equipment standards for high reliability and productivity.

Technical Advantages

1. Precision Flanging

- Supports 5-layer stacked flanging (4 layers + base layer)

- Accurate width control: 7mm/10mm selectable

- Compatible with insulation paper: 0.10-0.21mm thickness

2. High-Efficiency Production

- Variable-frequency stepless speed control: 0-20m/min

- 8-blade rotary cutting unit: Φ84mm alloy blades

- Continuous non-stop feeding design

Performance Parameters

Material Specifications:

- Paper roll core ID: Φ76mm

- Paper roll OD: ≤Φ400mm

Processing Range:

- Paper width: 160-800mm

Mechanical Configuration:

- Cutting blades: 8×Φ84mm alloy blades

Efficiency:

- Max flanging speed: 20m/min

Energy Requirements:

- Power: 1.1kW 3-phase 380V

- Compressed air: 0.6MPa (consumption: 0.2m³/min)